Home / Products / Aluminum T-Slot Frames

Aluminum T-Slot Frames

When you need to build custom structures like workbenches or carts, you may consider welding steel. We provide you the solutions to create your structures by using aluminum T-slot frames.

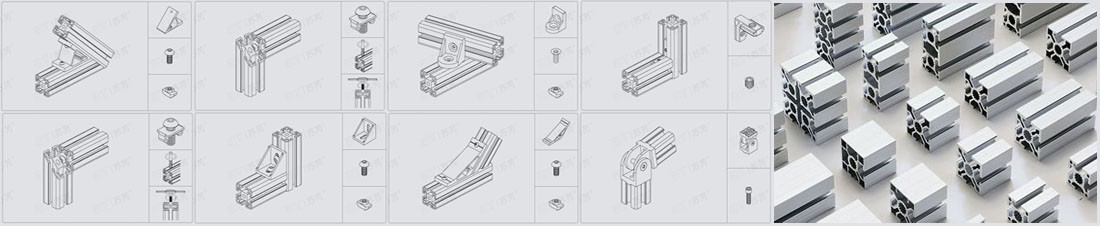

We manufacture a wide range of T-slotted aluminum extrusions and required connectors & fasteners to fit all your needs, whether you are looking to build a full structural or modular T Slot aluminum framing project or a simple sign. You can simply insert T-nuts and tighten them into the extrusions to build a durable and lightweight aluminum framing system, in aluminum natural anodized finishes or to your custom specifications.

Most of our aluminum T-slot extrusions are standard in metric sizes, our open extruding dies include extrusions of 16 series, 20 series, 25 series, 30 series, 40 series, 45 series, 60 series, 80 series, 90 series and 100 series. Connectors & fasteners include T-nuts, square nuts, T-bolts, connection screws, corner brackets, corner gussets, angle connectors, threaded inserts, connection plates, hinges, profile sliders and end caps. With the components we provide, you can create functional and attractive products like workbenches, tables, sighs, shelves, enclosures, aquarium stands and carts.

What are T-slot extrusions?

T-Slot aluminum extrusion is a kind of beam made from extruded aluminum. These appear and can act as excellent tools to assemble any given product without much chaos. We aim at creating and providing such high performance assemblies that can help in building attractive end products like the work benches, tables, sighs, shelves, enclosures, carts and more.

Why we create high quality assemblies by using T-Slot extrusions?

Today’s engineering and the budding professionals are under a great pressure to complete any given work way ahead of time and so, the quality as well as the outcome of their work is badly affected. This could be the common complaint, however, we aim at providing top class structures in the form of aluminum T Slot extrusions that can fit in well and can act as high quality assemblies.

Advantages of aluminum extrusions:

Aluminum extrusion is the crucial step in constructing T-slots that can help in managing high performance assemblies. Here are a few advantages that can be associated with Aluminum extrusion. They include:

- Extrusion is a beneficial process because of the cost benefits associated with it.

- It is also advantageous because of the structural integrity within the metal.

- Aluminum is exploited for numerous construction material as it can be used for adding metal accents and more.

- These aluminum extrusions, particularly T-slots will have standard metric sizes that can be attributed to the standard die cuts. These therefore can go great with connectors and fasteners such as square nuts, bolts, screws, corner brackets and more, thus managing to provide a precise assembly.

The process:

Process involved in producing the desired aluminum T Slot extrusion is easily understandable. Here is how the extrusion process works.

- Extrusion is a process of shaping different molten materials.

- Aluminum in its molten state is moulded into T-slots under high pressure.

- It could be done under hot or cold conditions as a continuous or semi continuous process.

The extruded aluminum finds great application because of the underlying benefits of the material such as reusability and recyclability. The material could be melt down easily and can be completely recycled into another one as such, thus keeping the environment friendly spark alive within those willing to use T-slot extrusion particularly made of aluminum.

Contact us today to request a quote for your custom project by using T-slot aluminum extrusions.

Use our manufacturing services for your project, get in touch today!

Send us an email at [email protected] or fill in the RFQ form to get a quote from us, we will get back to you in 24 hours!