Home / Products / Standard Aluminum Extrusions / Aluminum Round Tubes

Aluminum Round Tubes

We carry a large inventory of extrusion tooling for standard aluminum extrusions designed to National, American and European standard specifications. 6063 and 6061 is the most common aluminum alloy for the standard shapes, surface finish can be mill, anodized and powder coated.

We carry a large inventory of extrusion tooling for standard aluminum extrusions designed to National, American and European standard specifications. 6063 and 6061 is the most common aluminum alloy for the standard shapes, surface finish can be mill, anodized and powder coated.

Please specify alloy, length, surface finish, quantity and your special requests when you need to order a standard aluminum shape.

Commonly used alloys for Aluminum Round Tubes

The 6063 and 6061 are the most commonly used alloys for extruded aluminum including aluminum tubes and other aluminum extrusions. The multiple aluminum round tube sizes allow for their diversified uses and applications, they are mostly used in general construction and structural applications.

- The 6061 aluminum round tube is known for its flexibility in terms of its machine-use or use in welding. It is highly resistant to corrosion and has a relatively high strength-to-weight ratio, which is why it is commonly used in most industrial applications. This form of aluminum extruded product is also widely used in making heavy-duty structures whose basic requirement is to be resistant to corrosion. This product can be further toughened by exposing it to heat.

- 6063 aluminum alloy is the most popularly used alloy for extruded aluminum. Magnesium and Silicon are used as the alloying elements. It is used in making door and window frames, signs, roofs, pipes and tubes. Aluminum round tubes made of 6063 alloy with t5 tempered can be one of the most used standard materials you can see everywhere.

Difference between 6061 and 6063 alloys used for aluminum extrusions

- The strength-to-weight ratio is higher in 6061 as compared to 6063.

- 6061 alloy is high on weldability and machinability. While 6063 is used for making shapes that require smooth surface.

- The 6061 alloy has a density of 2.7g/cm cube. 6063, on the other hand has a density of 2.69 g/cm cube.

- The Young’s module for the 6061 is 68.9 GPa while that of 6063 is 68.3 GPa.

- The tensile strength of the 6061 alloy varies between 124-290 MPa whereas the 6063’s tensile strength fluctuates between 145 -186 MPa.

- The linear thermal expansion coefficient of 6061 is 2.32 10−5 K−1 and that of the 6063 alloy is 2.34 x 10−5 K−1.

Uses of Aluminum Round Tube

This kind of extruded aluminum is used mainly in –

- Preparing fittings, couplers, sleeves, valves and shafts, bicycle frames and other types of framework.

- Aerospace, oil & gas, furniture, automotive, railways and marine industries.

- Railings, trim, protective structural components and electrical fittings.

- Toys, gangways and aluminum docks.

The aluminum round tube sizes vary and can be customized as per client’s requirement. Our readily made and easily available sizes fluctuate between 10 mm to 400 mm diameter; and the weight contrast from 0.06 kg/meter to 15 kg/meter.

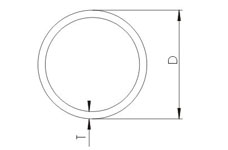

The following is list for a part of our open tooling for aluminum round tubes. If you are looking for an individual size, please feel free to contact us and request a quote.

| Part # | D (mm) | T (mm) | Kg/meter |

|---|---|---|---|

| XXR02-20 | 10 | 0.85 | 0.066 |

| XXR02-3 | 10 | 1.5 | 0.109 |

| XXR14-5 | 12 | 1.65 | 0.145 |

| XXR313 | 12.7 | 1.59 | 0.150 |

| XXR36-16 | 13 | 1.2 | 0.121 |

| XXR36-17 | 13 | 1.4 | 0.138 |

| XXR36-68 | 14 | 2.8 | 0.267 |

| XXR04-32 | 15.5 | 1.3 | 0.157 |

| XXR18-05 | 16 | 0.7 | 0.092 |

| XXR36-19 | 16 | 1.0 | 0.128 |

| XXR04-80 | 16 | 1.3 | 0.163 |

| XXR36-14 | 16 | 1.4 | 0.155 |

| XXR03-4 | 16 | 1.6 | 0.196 |

| XXR02-93 | 17 | 1.0 | 0.136 |

| XXR14-4 | 17.7 | 2.8 | 0.350 |

| XXR0319 | 19 | 0.85 | 0.131 |

| XXR0336 | 19 | 1.2 | 0.182 |

| XXR36-18 | 19 | 1.3 | 0.196 |

| XXR10-79 | 19 | 1.6 | 0.244 |

| XXR01-8 | 19.3 | 1.05 | 0.168 |

| XXR25-26 | 20 | 0.95 | 0.162 |

| XXR25-25 | 21.7 | 1.1 | 0.168 |

| XXR36-47 | 22 | 0.8 | 0.144 |

| XXR02-92 | 22 | 1.0 | 0.179 |

| XXR0322 | 22 | 1.2 | 0.213 |

| XXR36-31 | 22 | 1.5 | 0.262 |

| XXR11-12 | 22 | 2.0 | 0.341 |

| XXR18-03 | 22 | 6 | 0.817 |

| XXR01-7 | 22.1 | 1.1 | 0.204 |

| XXR05-3 | 22.2 | 1.2 | 0.215 |

| XXR01-6 | 24.9 | 1.05 | 0.223 |

| XXR05-1 | 25 | 1.0 | 0.204 |

| XXR36-32 | 25 | 1.2 | 0.243 |

| XXR11-15 | 25 | 1.4 | 0.282 |

| XXR03-05 | 25 | 1.5 | 0.300 |

| XXR11-13 | 25 | 2.0 | 0.392 |

| XXR09-08 | 25 | 3.0 | 0.562 |

| XXR18-04 | 25 | 5.9 | 0.954 |

| XXR33-2 | 28 | 1.0 | 0.230 |

| XXR02-69 | 29 | 1.1 | 0.261 |

| XXR03-6 | 30 | 2.0 | 0.477 |

| XXR02-10 | 31.2 | 6.1 | 1.304 |

| XXR31-1 | 31.7 | 3.4 | 0.819 |

| XXR10-80 | 31.75 | 1.45 | 0.374 |

| XXR30-17 | 33.5 | 6.0 | 1.405 |

| XXR09-4 | 34.6 | 1.1 | 0.314 |

| XXR01-01 | 36 | 4.0 | 1.090 |

| XXR02-9 | 38.2 | 3.3 | 0.981 |

| XXR33-1 | 40 | 1.0 | 0.332 |

| XXR10-41 | 42.2 | 3.6 | 1.183 |

| XXR18-02 | 46 | 2.0 | 0.749 |

| XXR10-38 | 48.2 | 2.7 | 1.046 |

| XXR10-165 | 48.3 | 3.7 | 1.405 |

| XXR02-261 | 48.6 | 5.0 | 1.856 |

| XXR0350 | 50 | 1.4 | 0.579 |

| XXR02-49 | 50 | 5.0 | 1.916 |

| XXR18-01 | 50.5 | 1.8 | 0.727 |

| XXR30-28 | 51.3 | 5.65 | 2.364 |

| XXR11-14 | 54.5 | 3.2 | 1.398 |

| XXR0356 | 56 | 1.5 | 0.696 |

| XXR12-5 | 58 | 4.0 | 1.839 |

| XXR18-07 | 58 | 2.5 | 1.181 |

| XXR30-29 | 61.3 | 5.65 | 2.677 |

| XXR0364 | 64 | 1.45 | 0.798 |

| XXR18-06 | 64 | 2 | 1.056 |

| XXR18-10 | 68 | 2.5 | 1.394 |

| XXR01-6 | 69.9 | 16.9 | 7.672 |

| XXR83-1 | 82.4 | 3.5 | 2.578 |

| XXR0300 | 100 | 1.2 | 1.076 |

| XXR03120 | 120 | 1.4 | 1.414 |

| XXR02-102 | 143 | 2.3 | 2.696 |

| XXR30-37 | 152 | 13.25 | 15.652 |

| XXR02-38 | 180 | 1.8 | 2.731 |

| Part # | D (mm) | T (mm) | Kg/meter |

Use our manufacturing services for your project, get in touch today!

Send us an email at [email protected] or fill in the RFQ form to get a quote from us, we will get back to you in 24 hours!