Aluminum Extrusions and Custom Fabrication Services

With annual output over 100,000 tons of extruded aluminum profiles, Xinxiang owns one of the largest extrusions manufacturing plant in China. We have 28 aluminum extruders ranging from 600 to 5000-tons and several surface treatment lines as well offering in-house finishing processes, which include polishing, anodizing and powder coating. By using our cutting edge technology to ensure the order’s accuracy, we always provide high-quality custom extrusions for a variety of industrial groups in the world.

Besides, our aluminum fabrication plant makes us act as a ‘One-stop’ manufacturer for custom aluminum parts & fabricated aluminum products, allowing us to meet our customers’ varied needs and provide our clients with custom aluminum components at very competitive rates.

Aluminum Extrusions / Custom Aluminum

We specialize in manufacturing aluminum profiles and custom aluminum parts to many industrial groups. Our past clients include building & construction, automotive, electronics, agricultural, new energy companies and many other manufacturing companies.

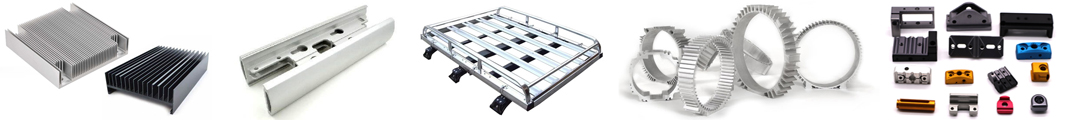

Our extruded aluminum shapes include standard aluminum extrusions such as aluminum round tubes, square tubes, aluminum flat bars, aluminum angles and channels, aluminum window & door profiles, aluminum heatsinks, aluminum T-slot frames, motor housings and custom extrusions. We also provide aluminum fabrication services based on extruded aluminum, our aluminum CNC machined parts and custom fabricated components are widely used in applications including furniture frames, auto spare parts, air conditioners, LED lighting enclosures, motor housing, conveyor systems, heat sinks, framings and brackets for solar panels, electrical machinery and equipment, medical equipment, sports equipment.

Aluminum Manufacturing Capabilities

We offer extensive and varied range of processing services in our fabrication plant, including precise cutting, custom CNC machining, bending, pressing and welding fabrication. When it comes to final surface finishing such as aluminum anodizing and powder coat, we can produce high quality aluminum products to meet our clients’ specifications thanks to our in-house finishing processes. We truly are a one-stop custom aluminum parts manufacturer for our customers.

WHY CHOOSE US OVER OTHER ALUMINUM EXTRUSION MANUFACTURERS?

People

Our sales team, technical team, production and QC members average nearly 10 years of experience in aluminum industry is a huge benefit to our clients. We frequently help them design custom extrusions and get involved in the early stages of product design, to ensure the right alloy and extrusion design to be used. This always helps to achieve quality and cost effective products.

Fabrication

Many China aluminum manufacturers only produce aluminum extrusion profiles, which makes it difficult to accommodate all the needs of their clients. We provide a full range of aluminum CNC machining & custom aluminum fabrication services to our clients, we act as a ‘One-Stop Shop’ for aluminum products.

Quality

We believe ‘Quality Comes First’, from extrusion shapes design, extruding, fabrication, surface finishing to final assembly & package, we always pay close attention to the quality to ensure our clients receive high-quality aluminum products.

Cost Savings

We truly are manufacturer to create aluminum parts from raw aluminum alloy, we even cast aluminum billets which are used to extrude aluminum profiles. Therefore we can offer our clients best price for their projects.

Use our manufacturing services for your project, get in touch today!

Send us an email at [email protected] or fill in the RFQ form to get a quote from us, we will get back to you in 24 hours!