Home / Products / Aluminum Heatsinks / Black Heat Sinks

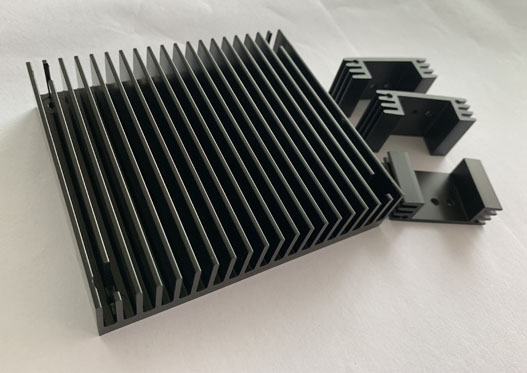

Black Heat Sinks

Aluminum heatsinks have been widely used in PCB, computers, lightings, electronic devices and other cooling systems that require constant heat dissipation. As a stable metal object, aluminum heat sink can be customized and produced through various processing methods. Due to the advantages of stable quality, environmental protection, corrosion resistance, standard shapes & customization, low cost and efficient heat dissipation, aluminum heat sinks play an important role in various cooling systems. The black heatsinks we often see in many applications are actually aluminum heat sinks that are anodized in black color. Besides black anodized finish, there are many other finishes options for a heat sink. You will find out as below why black anodized finish is commonly used on a heat sink.

Aluminum heatsinks have been widely used in PCB, computers, lightings, electronic devices and other cooling systems that require constant heat dissipation. As a stable metal object, aluminum heat sink can be customized and produced through various processing methods. Due to the advantages of stable quality, environmental protection, corrosion resistance, standard shapes & customization, low cost and efficient heat dissipation, aluminum heat sinks play an important role in various cooling systems. The black heatsinks we often see in many applications are actually aluminum heat sinks that are anodized in black color. Besides black anodized finish, there are many other finishes options for a heat sink. You will find out as below why black anodized finish is commonly used on a heat sink.

Several different surface finishes for aluminum heatsinks

Choosing the right surface treatment is what aluminum heatsinks often need to face. According to different price levels, product characteristics, functional requirements and decorative effects, the heat sinks can have a variety of surface options.

If low cost is the priority, considering that aluminum alloy is a relatively corrosion-resistant metal, in many cases the natural plain silver surface of aluminum metal is good. At this time, the radiator is the plain silver color. In fact, the slightly corroded aluminum pieces under natural conditions do not seriously affect the heat dissipation effect of the radiators. Under these conditions, aluminum heatsinks made out of different manufacturing processes will have roughly the same aluminum metal surface, but there are still some differences. For example, an extruded heat sink presents extruded surface from aluminum alloy with slight squeezing marks. The surface of a die-cast heat sink will appear darker color due to the alloy materials, while the skived fin heatsinks will have obvious processing marks. Others like bonded fins heatsinks will show the initial surface of the plate materials.

For aluminum products, the most common surface treatment process is anodizing, which is characterized by generating a dense oxide film on the surface of the pieces. Anodizing process can be applied on most aluminum alloy materials. The process is not complicated and the cost is not too high. The oxide film produced is very stable under normal circumstances, corrosion resistance and can turn out to be a decorative appearance. Therefore, anodizing has become the most commonly used surface treatment process for aluminum radiators. Among them, the most common anodized finishes are aluminum natural anodized finish and black anodized finish. If there is a special decorative requirement, anodizing can also make the workpiece show different colors, but its cost will be relatively higher than that of natural silver and black cover.

In addition, according to specific needs, aluminum heat sinks can also be polished, electroplated, sprayed and other surface treatments. However, remember that a thicker surface film will have a negative impact on the heat dissipation effect of the heat sink, which need to be avoid.

Why is black anodized finish a favorite surface treatment for aluminum heatsinks to many consumers?

Firstly, as mentioned above that the anodized surface treatment of aluminum products has the advantages of corrosion resistance, high stability and low cost, so it is a commonly used surface treatment for aluminum heat sinks. Because anodized in black color, matt or gloss, is usually more beautiful than the aluminum natural silver color, and is considered to be only slightly higher in cost, so that black anodized finish can be a surface treatment that many consumers prefer.

Secondly, some test results show that the black heat sinks has a more efficient heat dissipation performance. In a heat dissipation system that has strong forced-air cooling device, the black anodized heatsinks perform almost the same heat dissipation effect as the ones in natural silver color. But in a low airflow cooling system, the black heatsinks will have a better heat dissipation effect of about 10% increase. Although this is a relatively small difference, black heatsink is undoubtedly a better choice from a more professional and technical selection. Summarizing our past customer’s choices, about half of them ultimately choose to use the black aluminum heat sinks.

Use our manufacturing services for your project, get in touch today!

Send us an email at [email protected] or fill in the RFQ form to get a quote from us, we will get back to you in 24 hours!